In aerospace, every technological innovation and breakthrough marks a step into the unknown. Ripple MFG, as a leader in this field, has injected new vitality into the development of the aerospace field with its unique technical advantages and brand characteristics.

Prototyping: Exploring the Future of Aerospace

The aerospace field is extremely demanding in terms of technology, and every detail may affect the performance of the final product. Therefore, prototyping plays a pivotal role in aerospace R&D. Ripple MFG's custom prototype manufacturing service provides aerospace designers with a platform to realize their creativity through its efficient and accurate manufacturing capabilities. Through prototype testing, designers can visualize the actual effect of their designs and then optimize and adjust them. This not only shortens the research and development cycle, but also greatly improves the research and development efficiency, providing a strong guarantee for the innovation in the aerospace field.

Rapid tooling: accelerating the aerospace R&D process

In the aerospace R&D process, the preparation of production tools is a time-consuming and complex task. However, Ripple MFG's Rapid Tool service is able to respond quickly to R&D needs and provide high-quality production tools. This service not only reduces tooling time, but also improves tooling accuracy and stability, which accelerates the aerospace R&D process. At the same time, this also enables the R&D team to focus more on product innovation and optimization, promoting the continuous progress of aerospace technology.

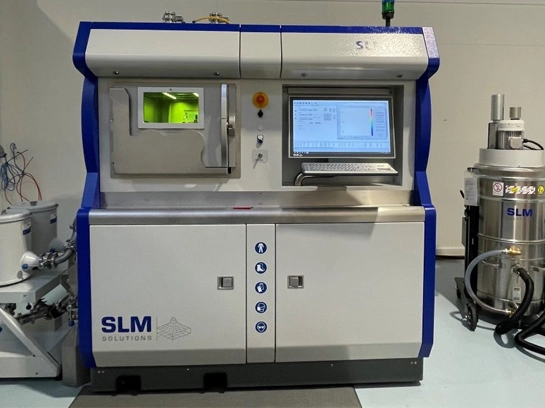

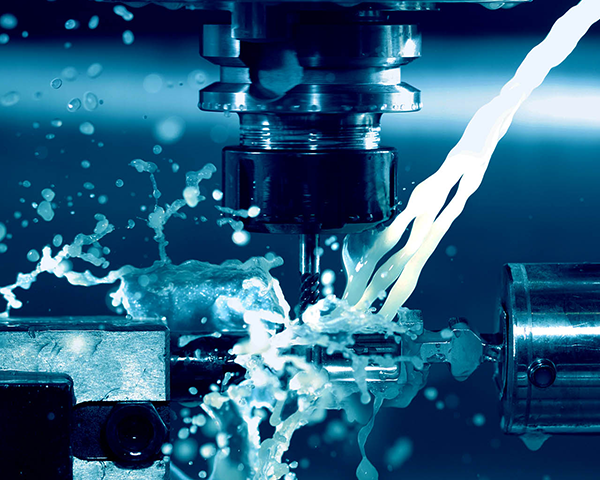

Custom prototype manufacturing technology: meeting complex aerospace needs

Aerospace custom prototype manufacturing involves a wide range of materials and processes, requiring manufacturers to have diversified technical capabilities, and Ripple MFG is one such enterprise with diversified manufacturing technologies. Ripple MFG is a company with a wide range of manufacturing technologies, including Plastic Molding, Plastic Mold, CNC Machining, 3D Print Vacuum Casting, Insert Mold and Die Casting. The application of these technologies enables Ripple MFG to meet the complex needs of aerospace manufacturing, whether it is the manufacture of high-precision components or the machining of complex structures. This not only ensures the quality and performance of aerospace products, but also provides more possibilities for product innovation.

Customized services: promoting the development of aerospace personalization

With the continuous development of aerospace technology, the need for personalization has gradually come to the fore. Whether it is a unique aircraft design or specific functional requirements, manufacturers are required to provide customized solutions. with its strong technical strength and flexible customization capabilities, Ripple MFG is able to provide customers with personalized aerospace prototyping services. Whether it is a customized design based on customer needs or a customized production based on specific requirements, Ripple MFG is able to achieve excellence and ensure that every product meets customer expectations. This customized service model not only promotes the personalized development of the aerospace field, but also injects new vitality into the whole industry.

In summary, Ripple MFG plays an important role in the field of customized prototyping in aerospace innovation with its unique brand advantages and technical strength. Its efficient prototyping, rapid tool preparation, diversified manufacturing technologies and personalized customization services have injected new vitality into the innovation and development of the aerospace field. We have reason to believe that the aerospace field will usher in a brighter future under the impetus of Ripple MFG and other outstanding enterprises.

- What Are the Process Steps for Cast Urethane Prototypes?September 14, 2024Polyurethane resin is a versatile material used to produce various plastic products. Its applications are diverse because it can produce both flexible, almost rubber-like products, and rigid plastics....view

- What Are the Applications of 4-Axis CNC Machining Services?September 14, 2024About 4-Axis CNC Machining ServicesIn 4-axis CNC milling, the fourth axis is added to the movement of the cutting tool, allowing it to rotate around the x-axis. Now, there are four axes: the x-axis, y...view

- The Role of Custom Rapid Prototyping in Product DevelopmentMarch 19, 2024With the increasingly fierce competition in the market, the speed and quality of product development have become the key factors for the success of enterprises. Among them, custom rapid prototyping pl...view

- Custom Prototype Manufacturing in ConstructionMarch 19, 2024In the construction industry, custom prototype manufacturing is a critical component to ensure a smooth project, and Ripple MFG stands out in the field of custom prototype manufacturing in const...view

- What Is Pressure CastingFebruary 27, 2023Introduction to Pressure CastingPressure casting is a casting method in which molten or semi-molten metal is pressed into the metal casting mold at high speed and crystallized under pressure, referred...view

- Beyond 3D Printing: Exploring Precision Prototyping MachiningOctober 27, 2023The world of manufacturing and rapid prototyping has seen significant advancements in recent years. While 3D printing has gained immense popularity for creating prototypes and functional parts, there&...view