Welcome to the fascinating world of nanotechnology, where scientists and engineers manipulate matter at the tiniest scale. Unlocking the potential of this field requires the use of high precision tools that enable precise measurements and control. In this blog, we will explore the importance of high precision tools in nanotechnology applications and how they contribute to advancements in various industries.

The Role of Nanotechnology in Innovation

Nanotechnology has revolutionized numerous industries, ranging from electronics and medicine to materials science and energy. By working with materials at the atomic and molecular level, scientists have been able to develop novel applications that were once inconceivable. However, to fully harness the potential of nanotechnology, the use of high precision tools becomes paramount.

Understanding High Precision Tools

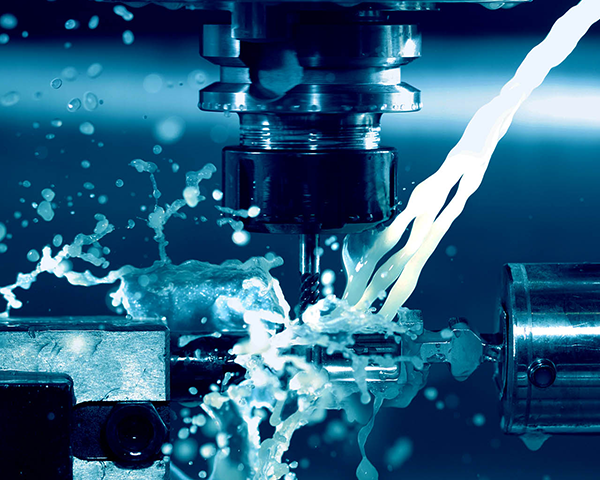

High precision tools refer to instruments that have an incredibly accurate measurement capability and enable fine control at the nanoscale. These tools are designed to meet the demanding requirements of nanotechnology experiments and manufacturing processes. Examples of high precision tools include scanning electron microscopes (SEMs), atomic force microscopes (AFMs), nanopositioning systems, and nanoscale 3D printers.

Enabling Precise Measurements and Analysis

One of the key benefits of high precision tools in nanotechnology is their ability to provide accurate measurements and detailed analysis. Instruments like SEMs and AFMs allow researchers to visualize and analyze nanoscale structures with exceptional resolution. This capability is crucial in understanding the behavior of materials, studying nanoscale phenomena, and developing innovative applications.

Facilitating Nanofabrication and Manufacturing

High precision tools also play a vital role in nanofabrication and manufacturing processes. Nanoscale 3D printers enable the creation of intricate structures with high precision, allowing for the design and production of new materials with unique properties. Furthermore, nanopositioning systems provide the necessary control to manipulate nanoscale objects, aiding in the assembly of nanodevices and facilitating the development of nanosensors and other sophisticated instruments.

As nanotechnology continues to advance and integrated into various industries, the importance of high precision tools cannot be overstated. These tools enable scientists and engineers to navigate the nanoworld, empowering them to make breakthroughs and push the boundaries of what is possible. From precise measurements and analysis to intricate nanofabrication, high precision tools are the backbone of nanotechnology applications. With continued advancements in these tools, we are poised to unlock new capabilities that will revolutionize a wide range of sectors and improve our quality of life. So next time you hear about a groundbreaking nanotechnology application, remember that behind it lies the power of high precision tools.

- Automotive Ingenuity: Revolutionizing Vehicle Design with Prototype MachiningJanuary 5, 2024In the modern automotive industry, innovation and technology play an integral role in shaping the future of vehicles. One process that stands out amidst this evolution is prototype machining. With its...view

- Prototype Machining Services: High-Efficiency Product OptimizationDecember 23, 2024What is Prototype Machining?Prototype machining is a manufacturing process used to create samples or prototypes of a product. It typically uses computer-aided design (CAD) software and computer numeri...view

- Efficiency Redefined: The Impact of High Precision Tools in IndustriesJanuary 5, 2024In the ever-evolving landscape of industrial manufacturing, the pursuit of efficiency is paramount, and at the core of this quest lies the transformative impact of high precision tools. These sophisti...view

- The Future of Manufacturing: Urethane Casting Services in a Dynamic IndustryJanuary 5, 2024In the ever-evolving landscape of manufacturing, where precision, flexibility, and speed are paramount, the future is being shaped by innovative technologies like urethane casting services. This dynam...view

- What is the Tolerance of a 5 Axis CNC Machine?September 19, 2023What is 5 Axis CNC Machining?5 axis CNC machining is a type of computer-controlled machining that uses five axes of motion to cut and shape materials. The five axes allow for greater flexibility and p...view

- Innovation Unleashed: the Role of Prototype Machining in Product DevelopmentJanuary 5, 2024In the dynamic realm of product development, where ideas evolve into tangible innovations, the role of prototype machining stands as a cornerstone for success. The journey from concept to market-ready...view