The Importance of Precise Tool and Manufacturing Technology

In modern industry, the application of precise tools and manufacturing is becoming increasingly widespread. They are not only a symbol of technological progress but also a powerful driving force that propels the entire industrial system forward. From tiny electronic components to large mechanical equipment, precise tools and manufacturing technology are involved, profoundly changing our production methods and quality of life. Ripple MFG is a precise tool and manufacturing company that has always adhered to the service philosophy of "customer first", aiming to provide customers with more product choices.

Ripple MFG's Precise Tool and Manufacturing Technology

To provide the best service to customers, Ripple MFG, a professional prototype manufacturing company, has honed its skills in manufacturing custom molds, dies, and tools. These tools are specifically designed to produce your products and components to the highest standards. Ripple MFG has an expert team dedicated to supporting your internal tooling needs. They possess the necessary skills and highly specialized technology to design, manufacture, and maintain complex tools used for producing your equipment and components. The main services include:

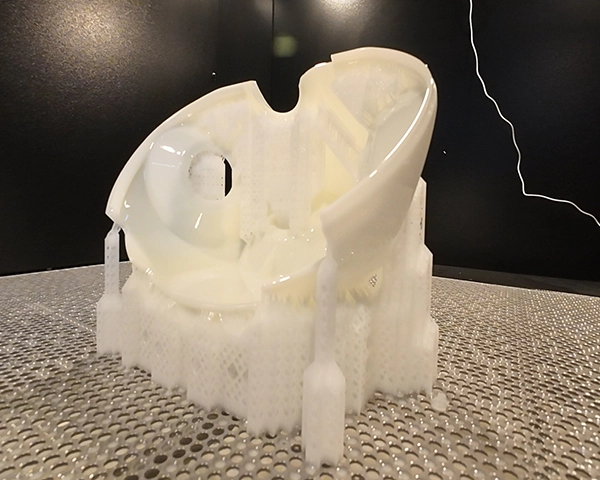

Prototype and Rapid Tooling

This precise tool and manufacturing process involves creating initial models or samples, allowing precise tool manufacturers to test and refine designs before full-scale production. Specifically, rapid tooling is a quick and cost-effective method for producing prototypes for testing and validation.

Production Tools

The process of manufacturing durable and highly precise machine tools and molds for mass production. These high-precision tools are designed to withstand the rigorous demands of long-term production runs, ensuring consistent quality and efficiency throughout the manufacturing process.

Export Molds

Export molds require a deep understanding of international standards and regulations to ensure that the tools produced by precision mold suppliers meet the requirements of overseas manufacturers.

- Sports Equipment Redefined: Urethane Casting Services in Athletic Gear ManufacturingJanuary 5, 2024In the ever-evolving world of sports gear manufacturing, innovation is key to staying ahead of the game. As athletes continually strive to push their limits, manufacturers must find ways to deliver eq...view

- The Role of Cast Urethane Services in Automotive LightweightingJune 14, 2024With the development of various automobile companies, the competition in the automotive industry is becoming increasingly intense. Among all the competitive factors, cycle, quality, and cost are the t...view

- Harmony in Sound: 4 Axis CNC Machining for Musical Instrument SuppliersNovember 23, 2023When it comes to crafting musical instruments, precision and attention to detail are paramount. Whether it's a finely tuned guitar, a melodically rich piano, or a beautifully crafted violin, every...view

- Latest Trends in Precision Tool ManufacturingMarch 19, 2024As technology continues to advance, the field of precision tool manufacturing is witnessing an impressive array of recent trends. These trends not only drive the rapid development of the manufacturing...view

- Urethane Casting for Custom Parts: Your Key to InnovationOctober 27, 2023Innovation is the lifeblood of progress in product development, and for those seeking to create custom parts with precision and flexibility, urethane casting services are emerging as a pivotal solutio...view

- Food for Thought: Custom Prototyping in Culinary InnovationNovember 23, 2023Culinary innovation is an ever-evolving field that constantly seeks to push boundaries and tantalize our taste buds with new and exciting flavors. With the rise of the food and beverage industry, chef...view