Molds are indispensable basic technological equipment in the manufacturing industry, primarily used for efficient mass production of various industrial product components and parts. They are widely applied in important industries such as automotive, home appliances, transportation, and defense. Custom prototyping services, while improving prototype quality, ensuring final product quality, and meeting the ever-changing market demands, will also promote the overall competitiveness of the entire prototyping manufacturing industry.

The Necessity of Custom Prototyping Services

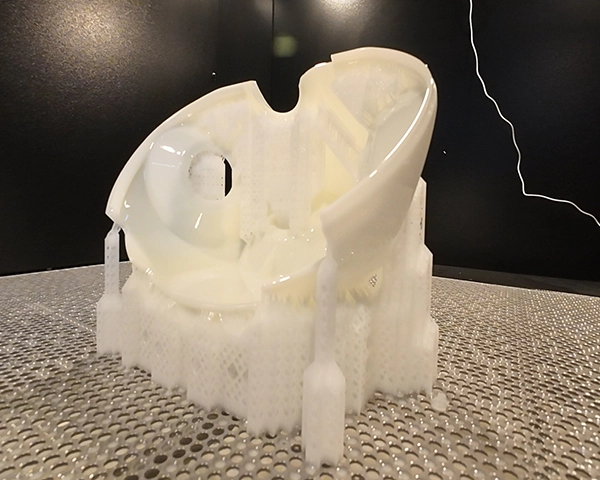

Each mold is composed of numerous components, and the quality of these components directly affects the overall quality of the mold. Precision machining technology is the foundation for ensuring the quality and performance of these components. This includes grinding, deburring& polishing, cleaning, and surface treatment. The core characteristic of precision molds is their high precision in operation, which requires more advanced equipment and technology during manufacturing and processing. Custom prototyping services ensure that molds can meet the stringent accuracy and quality requirements during production.

Precision Grinding Technology Solutions

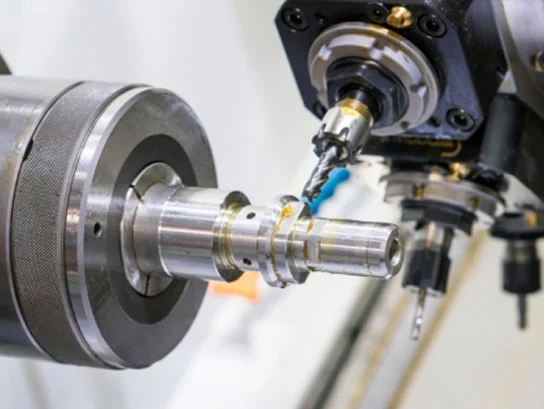

In the process of custom prototyping services, grinding work accounts for about 25% to 45% of the total manufacturing hours. The choice of equipment and processes is particularly important; otherwise, issues like grinding cracks, grinding marks, and grinding stress can arise, which not only damage the surface quality of the mold but also potentially shorten its lifespan. CNC milling is a highly automated processing technology. By precisely controlling the movement trajectory of the milling cutter through a computer numerical control system, it meets the stringent requirements for high precision and complex shape processing of mold cavities.

Accurately Grasp Market Demands

During the product development process, changes in market demand often have a significant impact on the product. Through custom prototyping services, prototype manufacturing companies can market-test the molds before actual production and collect user feedback. This method of accurately grasping market demands helps companies timely adjust product strategies, meet market needs, and enhance product competitiveness.

Optimizing Production Process Flow

In the product development process, optimizing the production process flow is crucial for improving production efficiency and reducing costs. Through custom prototyping services, companies can test the production processes of prototype products before actual production, identify bottlenecks and issues in the production process, and optimize and improve them. This way of optimizing the production process flow can save a significant amount of time and cost for companies, improving the efficiency and quality of product development.

In order to maintain a leading position in the fierce global market, the mold industry also needs to actively introduce high-end equipment and technologies, including precision machine tools and robotics. Custom prototyping services can create complex mold cavity structures that are difficult to achieve with traditional processes, promoting industry transformation and upgrading, and better meeting market demands.

- The Role of Cast Urethane Services in Automotive LightweightingJune 14, 2024With the development of various automobile companies, the competition in the automotive industry is becoming increasingly intense. Among all the competitive factors, cycle, quality, and cost are the t...view

- Applications of Precise Tool and ManufacturingSeptember 14, 2024About Ripple MFG's Precision Toolings ServicesAccording to Ripple MFG's global service strategy, it is dedicated to providing precision plastic injection molding services including...view

- What Are the Applications of 4-Axis CNC Machining Services?September 14, 2024About 4-Axis CNC Machining ServicesIn 4-axis CNC milling, the fourth axis is added to the movement of the cutting tool, allowing it to rotate around the x-axis. Now, there are four axes: the x-axis, y...view

- How Is Prototyping Used in the Automotive Industry?July 22, 2023Automotive rapid prototyping is an essential process used in the automotive industry to develop new vehicles and components. Prototyping allows designers and engineers to test and refine their ideas b...view

- What Are the Process Steps for Cast Urethane Prototypes?September 14, 2024Polyurethane resin is a versatile material used to produce various plastic products. Its applications are diverse because it can produce both flexible, almost rubber-like products, and rigid plastics....view

- What Is Precision Injection Molding?December 23, 2024Precision injection molding refers to an injection molding method where the dimensional repeatability of the molded products is very high, making it difficult to achieve the required standards using g...view

_20250123.webp)