As technology continues to advance, the field of precision tool manufacturing is witnessing an impressive array of recent trends. These trends not only drive the rapid development of the manufacturing industry, but also provide a broader market space for many companies. Against this backdrop, Ripple MFG has demonstrated strong competitiveness in a number of areas such as Prototype, Rapid Tool, Plastic Molding, etc., with its superior technology and unique brand advantages.

Deep integration of digital design and manufacturing

The extensive application of digital technology is becoming a major trend in the field of precision tool manufacturing, and Ripple MFG's Prototype service is a leader in this trend. With advanced digital design tools, Ripple MFG is able to quickly and accurately complete the design of product prototypes and realize efficient production through digital manufacturing technology. This deep integration not only improves manufacturing efficiency but also greatly reduces the time to market.

Customization and rapid response to become the market demand

With the increasing demand for consumer personalization, customized production is becoming a new trend in precision tool manufacturing, Ripple MFG's custom rapid prototyping service is designed for this market demand. Its highly efficient customized production process allows for rapid response to customer needs and the rapid manufacture of individualized products. This not only meets the diversified needs of the market, but also brings more business opportunities for enterprises.

The combination of composite materials and advanced technology

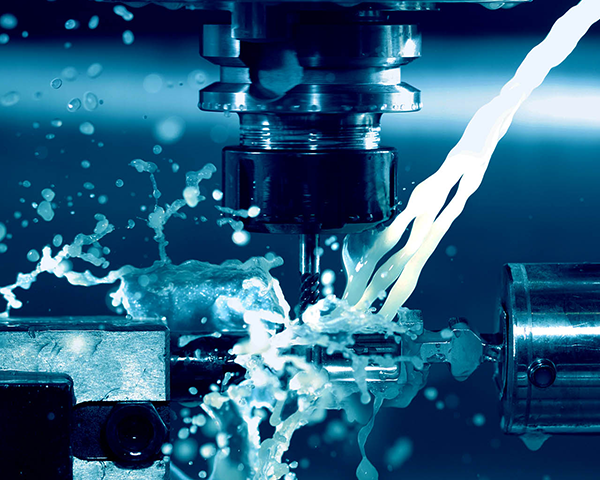

In precision tool manufacturing, the combination of composite materials and advanced technology is becoming the key to improve product performance, Ripple MFG has a deep accumulation of technology in Plastic Molding, CNC Machining and other fields. By utilizing these technologies, Ripple MFG is able to produce precision tools with excellent performance and stability, meeting the market demand for high quality products.

Green and Sustainable Development Becomes Industry Consensus

With the increasing awareness of environmental protection, green and sustainable development has become a consensus in the field of precision tool manufacturing, Ripple MFG focuses on environmental protection and rational use of resources in the production process, and is committed to promoting the development of green manufacturing. By adopting environmentally friendly materials and energy-saving technologies, Ripple MFG has made positive contributions to the sustainable development of the industry.

In summary, the deep integration of digital design and manufacturing, customization and rapid response, the combination of composite materials and advanced processes, as well as green and sustainable development are the latest trends in precision tool manufacturing. And Ripple MFG is leading the innovation and development in this field with its unique brand advantage and professional technical strength.

- Automotive Ingenuity: Revolutionizing Vehicle Design with Prototype MachiningJanuary 5, 2024In the modern automotive industry, innovation and technology play an integral role in shaping the future of vehicles. One process that stands out amidst this evolution is prototype machining. With its...view

- What Are the Process Steps for Cast Urethane Prototypes?September 14, 2024Polyurethane resin is a versatile material used to produce various plastic products. Its applications are diverse because it can produce both flexible, almost rubber-like products, and rigid plastics....view

- What Is Precision Injection Molding?December 23, 2024Precision injection molding refers to an injection molding method where the dimensional repeatability of the molded products is very high, making it difficult to achieve the required standards using g...view

- Knowledge Of Sheet Metal WorkingFebruary 27, 2023Introduction to Sheet Metal ProcessingSheet metal processing is a pivotal technology that sheet metal technical staff needs to grasp, and it is also an important process for forming sheet metal produc...view

- Medical Marvels: Innovations in Prototype Machining for Healthcare DevicesJanuary 5, 2024In today's rapidly advancing world, innovation in the healthcare sector has become essential for better patient outcomes. One area that has seen remarkable progress is prototype machining for heal...view

- What Is Pressure CastingFebruary 27, 2023Introduction to Pressure CastingPressure casting is a casting method in which molten or semi-molten metal is pressed into the metal casting mold at high speed and crystallized under pressure, referred...view