In modern industrial manufacturing, precision tools play a vital role. With the intensification of market competition, improving the efficiency of precision tool manufacturing has become an urgent need for the development of the industry. In this paper, we will discuss how to improve the efficiency of precision tool manufacturing through a series of strategies and technical means, especially with the unique brand advantage of Ripple MFG.

Optimize the prototype design and manufacturing process

Prototype design is the foundation of precision tool manufacturing, and Ripple MFG's Prototype service, with its high efficiency and accuracy, can quickly respond to design needs and shorten the prototype manufacturing cycle. Manufacturing efficiency can be significantly improved by optimizing prototyping and reducing unnecessary modifications and iterations. At the same time, Ripple MFG's customization service can carry out personalized prototype design and manufacturing according to customer-specific needs, thus ensuring efficient and accurate tool manufacturing.

Rapid tool preparation and iteration

In the precision tool manufacturing process, rapid tool preparation and iteration is the key to improving efficiency, and Ripple MFG's Rapid Tool service is able to respond quickly to production needs and provide high-quality production tools. Through the use of advanced manufacturing technology, Ripple MFG is able to shorten the tool preparation time, improve the accuracy and stability of the tool, thus ensuring the continuity and stability of the production line and improving manufacturing efficiency.

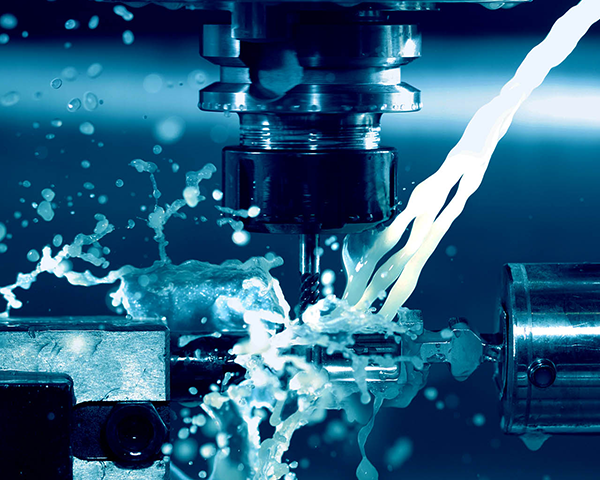

The application of innovative manufacturing technology

In the field of precision tool manufacturing, the application of innovative technology is an important driving force to improve efficiency, Ripple MFG has a deep accumulation of technology in the fields of Plastic Molding, Plastic Mold, CNC Machining, 3D Print Vacuum Casting, Insert Mold and Die Casting. Ripple MFG has accumulated profound technology and rich experience in the fields of Plastic Molding, CNC Machining, 3D Print Vacuum Casting, Insert Mold and Die Casting. The application of these technologies not only improves the manufacturing accuracy and efficiency, but also reduces the production cost, bringing a revolutionary change for precision tool manufacturing.

Intelligent and automated production

With the continuous development of intelligent manufacturing technology, intelligent and automated production has become an important means to improve the manufacturing efficiency of precision tools.Ripple MFG actively embraces the trend of intelligent and automated production, and realizes the automation and intelligence of the production process through the introduction of advanced robotics, automated production lines and intelligent management systems. This not only reduces labor costs, but also improves production efficiency and quality, further enhancing the competitiveness of precision tool manufacturing.

To sum up, we can effectively improve the efficiency of precision tool manufacturing by optimizing the prototyping and manufacturing process, rapid tool preparation and iteration, the application of innovative manufacturing technologies, as well as intelligent and automated production. And Ripple MFG, with its unique brand advantage and technical strength, provides strong support for the realization of this goal.

- Which Is Used for Machining Small Parts?July 22, 2023Small Part Machining: What is it?Small part machining is a process that involves removing material from a workpiece to create a smaller and more intricate part. Small parts are often used in a wide ra...view

- Custom Prototype Manufacturing in ConstructionMarch 19, 2024In the construction industry, custom prototype manufacturing is a critical component to ensure a smooth project, and Ripple MFG stands out in the field of custom prototype manufacturing in const...view

- Sculpting the Future: 4 Axis CNC Machining Suppliers for Artistic CreationsNovember 23, 2023Art and technology converge in a symphony of precision, giving rise to a new era in creative expression. As artists push the boundaries of their craft, the collaboration with cutting-edge technology b...view

- Exploring the Capabilities of 5 Axis CNC MachiningSeptember 1, 20235 axis CNC machining is a type of computer-controlled machining that utilizes five axes of motion to cut and shape materials. It is an advanced and versatile manufacturing process that is capable of p...view

- Timekeeping Triumphs: High Precision Tools in Watchmaking and HorologyJanuary 5, 2024In the intricate world of watchmaking and horology, where every tick of the clock is a testament to precision and craftsmanship, the role of high precision tools stands as the bedrock of excellence. T...view

- What Are the Process Steps for Cast Urethane Prototypes?September 14, 2024Polyurethane resin is a versatile material used to produce various plastic products. Its applications are diverse because it can produce both flexible, almost rubber-like products, and rigid plastics....view

_20250123.webp)