What is CNC Prototype Manufacturing?

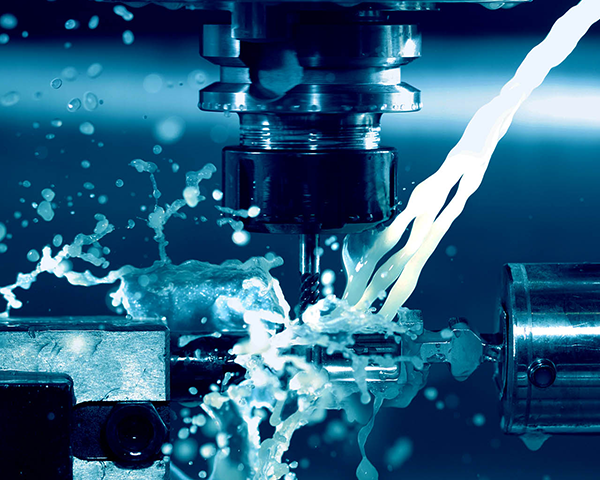

CNC prototype manufacturing is a type of prototype manufacturing that uses Computer Numerical Control (CNC) machines to create physical prototypes of products. CNC machines use a computer-controlled system to move cutting tools and other machinery to create precise and complex shapes from a variety of materials, including plastics, metals, and composites. CNC prototype manufacturing is a highly precise and efficient process that can create accurate and consistent prototypes quickly.

CNC custom prototype manufacturing is commonly used in the automotive, aerospace, and medical industries, where precise and complex parts are required. It is also used in the consumer goods industry, where it is used to create product prototypes and molds.

Advantages of CNC Prototype Manufacturing

There are several advantages to using CNC prototype manufacturing in the product development process.

Precise and Consistent Results

One of the biggest advantages of CNC prototype manufacturing is that it can create highly precise and consistent results. CNC machines use computer-controlled systems to move cutting tools and other machinery, which means that they can create highly accurate and complex shapes. This precision and consistency can help to ensure that the final product meets the required standards.

Fast Turnaround Time

CNC prototype manufacturing is a highly efficient process that can create accurate and consistent prototypes quickly. This means that prototype manufacturing companies can create prototypes faster and get products to market quicker. The fast turnaround time can be especially important in competitive industries, where time to market can be crucial.

Cost Savings

CNC prototype manufacturing can also help to save costs in the product development process. By creating highly precise and accurate prototypes, manufacturers can avoid costly mistakes down the line. CNC machines can also work with a variety of materials, which can help to reduce material costs. Additionally, the fast turnaround time can help to reduce labor costs and overall production costs.

Versatility

CNC machines can work with a variety of materials, including plastics, metals, and composites. This versatility can be especially important in industries where a wide range of materials are used. CNC machines can also create a variety of shapes and sizes, which means that they can be used to create complex and unique parts.

Automation

CNC machines are highly automated, which means that they require less manual labor than other types of prototype manufacturing. This can help to reduce labor costs and improve overall efficiency. Additionally, the automation can help to ensure consistent results, which can be important in industries where precision is crucial.

CNC prototype manufacturing is a highly precise and efficient process that can create accurate and consistent prototypes quickly. It is commonly used in industries where precise and complex parts are required, including the automotive, aerospace, and medical industries. There are several advantages to using CNC prototype manufacturing in the product development process, including precise and consistent results, fast turnaround time, cost savings, versatility, and automation. By using CNC prototype manufacturing, manufacturers can create prototypes quickly, reduce costs, and ensure that the final product meets the required standards.

- Prototype Machining Services: High-Efficiency Product OptimizationDecember 23, 2024What is Prototype Machining?Prototype machining is a manufacturing process used to create samples or prototypes of a product. It typically uses computer-aided design (CAD) software and computer numeri...view

- How Much Do You Know About The Process -- Vacuum CastingFebruary 27, 2023Why vacuum castingIn our daily life, we often apply to plastic products, in general products, the use of more thermoplastics, this plastic in industrial production, generally with thermoforming, can b...view

- Efficiency Redefined: The Impact of High Precision Tools in IndustriesJanuary 5, 2024In the ever-evolving landscape of industrial manufacturing, the pursuit of efficiency is paramount, and at the core of this quest lies the transformative impact of high precision tools. These sophisti...view

- Harmony in Sound: 4 Axis CNC Machining for Musical Instrument SuppliersNovember 23, 2023When it comes to crafting musical instruments, precision and attention to detail are paramount. Whether it's a finely tuned guitar, a melodically rich piano, or a beautifully crafted violin, every...view

- Knowledge Of Sheet Metal WorkingFebruary 27, 2023Introduction to Sheet Metal ProcessingSheet metal processing is a pivotal technology that sheet metal technical staff needs to grasp, and it is also an important process for forming sheet metal produc...view

- Innovation Unleashed: the Role of Prototype Machining in Product DevelopmentJanuary 5, 2024In the dynamic realm of product development, where ideas evolve into tangible innovations, the role of prototype machining stands as a cornerstone for success. The journey from concept to market-ready...view