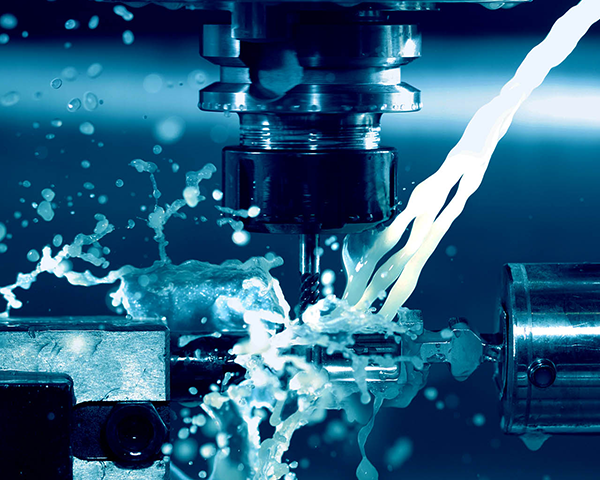

5 axis CNC machining is a type of computer-controlled machining that utilizes five axes of motion to cut and shape materials. It is an advanced and versatile manufacturing process that is capable of producing highly precise and complex parts. The additional two axes (A and B) that are added to the traditional 3 axis machining (X, Y, and Z) allow for greater flexibility and accuracy in machining parts.

Advantages of 5 Axis CNC Machining

5 axis CNC machining service offers several advantages over traditional 3 axis machining. One of the most significant advantages is its ability to produce complex shapes and contours with a high level of precision. The additional two axes allow the cutting tool to approach the material from different angles, which enables it to cut and shape the material in a way that is not possible with traditional 3 axis machines.

Another advantage of 5 axis CNC machining is its ability to produce parts with a high degree of accuracy and repeatability. The computer-controlled system ensures that the cutting tool moves exactly as programmed, which results in consistent and predictable results. This makes it an ideal choice for manufacturing applications where high precision is essential, such as aerospace and medical device manufacturing.

Additionally, 5 axis CNC machining can reduce the number of operations required to produce a part, which can help to reduce costs and improve efficiency. It can also reduce the amount of material waste, as it allows for more precise cuts that minimize the amount of excess material that needs to be removed.

Applications of 5 Axis CNC Machining

5 axis CNC machining, one of the custom CNC machining types, is widely used in industries such as aerospace, automotive, medical device manufacturing, and mold making. Its ability to produce complex and precise parts makes it an ideal choice for applications where high accuracy is essential. Here are some specific examples of what can be done with a 5 axis CNC machine:

Aerospace Components

5 axis CNC machining is widely used in the aerospace industry to produce parts such as turbine blades, engine components, and structural components. The complex shapes and contours required for these parts make them an ideal application for 5 axis CNC machining.

Medical Device Components

Medical devices require a high degree of precision and accuracy to ensure their safety and effectiveness. 5 axis CNC machining is commonly used to produce components for medical devices such as implants and surgical instruments.

Mold Making

5 axis CNC machining is an ideal choice for mold making due to its ability to produce complex shapes and contours. It is commonly used in the production of injection molds, which are used to manufacture a wide range of products, from automotive parts to household appliances.

Automotive Components

5 axis CNC machining is widely used in the automotive industry to produce parts such as engine blocks, transmission components, and suspension parts. Its ability to produce complex shapes and contours makes it an ideal choice for these applications.

Prototyping

5 axis CNC machining is also used in the prototyping phase of product development. Its ability to produce highly accurate and precise parts quickly and efficiently makes it an ideal choice for custom prototyping applications.

5 axis CNC machining is a highly advanced and versatile manufacturing process that is capable of producing complex and highly precise parts. Its ability to produce parts with a high degree of accuracy and repeatability, as well as its ability to reduce costs and waste, make it an ideal choice for a wide range of applications, from aerospace to automotive and medical device manufacturing.

- What Are the Applications of 4-Axis CNC Machining Services?September 14, 2024About 4-Axis CNC Machining ServicesIn 4-axis CNC milling, the fourth axis is added to the movement of the cutting tool, allowing it to rotate around the x-axis. Now, there are four axes: the x-axis, y...view

- What Are The Characteristics Of Precision CNC MachiningFebruary 27, 2023First, precision CNC machining process is concentratedCNC machine tools generally with automatic tool changer, tool magazine, tool change process automatically controlled by the program, therefore, th...view

- A Guide to CNC Prototype ManufacturingSeptember 1, 2023What is CNC Prototype Manufacturing?CNC prototype manufacturing is a type of prototype manufacturing that uses Computer Numerical Control (CNC) machines to create physical prototypes of products. CNC ...view

- Precise Tool and Manufacturing Technology: The Precise Force Driving Industrial ProgressSeptember 18, 2024The Importance of Precise Tool and Manufacturing TechnologyIn modern industry, the application of precise tool and manufacturing is becoming increasingly widespread. They are not only a symbol of tech...view

- What Is Pressure CastingFebruary 27, 2023Introduction to Pressure CastingPressure casting is a casting method in which molten or semi-molten metal is pressed into the metal casting mold at high speed and crystallized under pressure, referred...view

- Customized Prototyping in Aerospace InnovationMarch 19, 2024In aerospace, every technological innovation and breakthrough marks a step into the unknown. Ripple MFG, as a leader in this field, has injected new vitality into the development of the aerospac...view