Introduction to Injection Molding

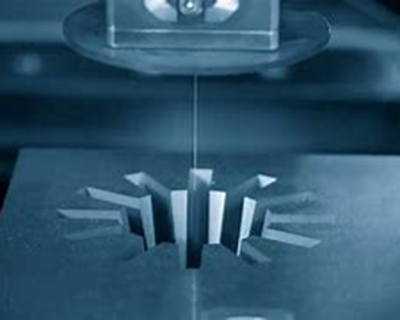

Injection molding is also known as injection molding, which is a kind of injection and molding method. The advantages of injection molding method are fast production speed, high efficiency, automatic operation, variety of colors, simple to complex shapes, large to small sizes, accurate product sizes, easy to update products, and the ability to form complex shaped parts, injection molding is suitable for mass production and complex shaped products and other molding processing fields.

History Of Injection Molding

In 1868, Hyatt developed a plastic material that he named celluloid. CELULU had been invented by Alexander Parkes in 1851. Hyatt improved it so that it could be processed into finished shapes. Hyatt, together with his brother Isaiah, registered the patent for the first plunger injection machine in 1872. This machine was relatively simple compared to the machines used in the 20th century. It operated basically like a giant hypodermic needle. This giant needle (diffuser cartridge) injected plastic into the mold through a heated cylinder. World War II in the 1940s created a huge demand for inexpensive, mass-produced products. In 1946, American inventor James Watson Hendry built the first precision injection molding machine, which allowed for more precise control of injection speed and quality of the items produced. This machine also allowed materials to be mixed prior to injection so that colored or recycled plastics could be thoroughly mixed for injection into virgin material. 1951 saw the development of the first screw injection machine in the United States, which was not patented, and this device continues to be in use. In the 1970s, Hendry went on to develop the first gas-assisted injection molding process and allowed the production of complex, hollow products that cooled quickly. This greatly increased design flexibility as well as the strength and endpoint of manufactured parts while reducing production time, cost, weight and waste.

- How Much Do You Know About The Process -- Vacuum CastingFebruary 27, 2023Why vacuum castingIn our daily life, we often apply to plastic products, in general products, the use of more thermoplastics, this plastic in industrial production, generally with thermoforming, can b...view

- Optimize Product Development Cycle with Custom Prototyping ServicesJune 14, 2024Molds are indispensable basic technological equipment in the manufacturing industry, primarily used for efficient mass production of various industrial product components and parts. They are widely ap...view

- The Role of Cast Urethane Services in Automotive LightweightingJune 14, 2024With the development of various automobile companies, the competition in the automotive industry is becoming increasingly intense. Among all the competitive factors, cycle, quality, and cost are the t...view

- Sports Equipment Redefined: Urethane Casting Services in Athletic Gear ManufacturingJanuary 5, 2024In the ever-evolving world of sports gear manufacturing, innovation is key to staying ahead of the game. As athletes continually strive to push their limits, manufacturers must find ways to deliver eq...view

- Customized Prototyping in Aerospace InnovationMarch 19, 2024In aerospace, every technological innovation and breakthrough marks a step into the unknown. Ripple MFG, as a leader in this field, has injected new vitality into the development of the aerospac...view

- What Are the Process Steps for Cast Urethane Prototypes?September 14, 2024Polyurethane resin is a versatile material used to produce various plastic products. Its applications are diverse because it can produce both flexible, almost rubber-like products, and rigid plastics....view