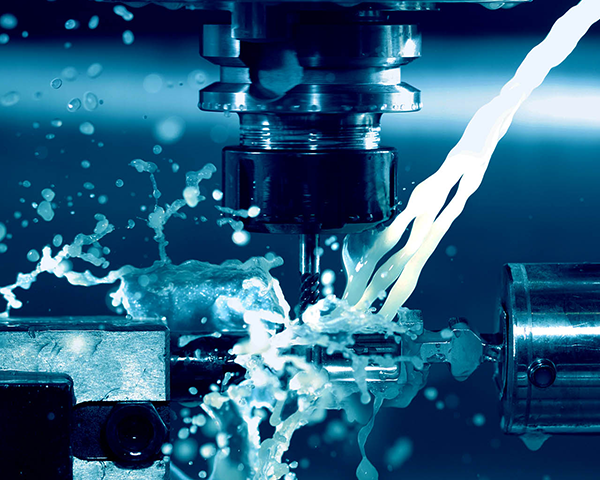

In the realm of manufacturing, precision is the name of the game. Nowhere is this more evident than in micro manufacturing, where the creation of tiny, intricate components is crucial for a wide range of industries, from electronics to healthcare. One technique that has revolutionized micro manufacturing is Precision Prototyping Machining. In this blog, we'll explore how this innovative method is making a big impact in the world of small parts.

Understanding Micro Manufacturing and Its Challenges

Micro manufacturing involves the production of extremely small parts and components, often with dimensions on the microscale (less than 1 millimeter). These machining small metal parts are used in various applications, from microelectronics and medical devices to aerospace and telecommunications. Achieving precision at such a small scale presents unique challenges that traditional manufacturing methods struggle to overcome.

The Role of Precision Prototyping Machining in Micro Manufacturing

Precision Prototyping Machining is an ideal solution for micro manufacturing for several reasons:

Exceptional Precision

The primary advantage of precision machining in micro manufacturing is its ability to achieve unparalleled precision. The method can produce components with tolerances measured in microns, ensuring that even the smallest of parts meet exacting specifications.

Material Versatility

Micro manufacturing often requires working with a diverse range of materials, from metals and ceramics to polymers and composites. Precision prototyping machining can handle these materials with ease, making it a versatile choice for various industries.

Complex Geometries

Manufactured by professional prototype manufacturing companies, micro components often have intricate and complex geometries. Machining can precisely create these intricate shapes with accuracy and consistency, a task that's difficult for many other manufacturing methods.

Scalability

While precision prototyping machining is widely used for prototyping, it's also a viable option for small to medium production runs. This scalability makes it cost-effective for manufacturers producing micro parts in larger quantities.

Applications of Precision Prototyping Machining in Micro Manufacturing

The applications of precision prototyping machining in micro manufacturing are extensive:

Microelectronics: Crafting tiny electronic components such as connectors, sensors, and microchips.

Medical Devices: Producing miniature medical implants, microfluidic devices, and surgical tools.

Telecommunications: Creating small connectors and components for communication systems.

Aerospace: Crafting intricate parts for space exploration and aviation.

Microfluidics: Developing lab-on-a-chip devices for scientific and medical research.

Precision Prototyping Machining is playing a vital role in micro manufacturing, enabling industries to create small parts with astonishing precision, versatility in material choices, intricate geometries, and scalability for production runs. As technology continues to advance, this method is poised to remain a cornerstone of micro manufacturing, providing the critical components that power modern technology and innovations in countless sectors. In the world of micro manufacturing, precision prototyping machining proves that small parts can indeed have a significant impact.

- Customized Prototyping in Aerospace InnovationMarch 19, 2024In aerospace, every technological innovation and breakthrough marks a step into the unknown. Ripple MFG, as a leader in this field, has injected new vitality into the development of the aerospac...view

- Food for Thought: Custom Prototyping in Culinary InnovationNovember 23, 2023Culinary innovation is an ever-evolving field that constantly seeks to push boundaries and tantalize our taste buds with new and exciting flavors. With the rise of the food and beverage industry, chef...view

- Exploring the Capabilities of 5 Axis CNC MachiningSeptember 1, 20235 axis CNC machining is a type of computer-controlled machining that utilizes five axes of motion to cut and shape materials. It is an advanced and versatile manufacturing process that is capable of p...view

- Prototype Machining Services: High-Efficiency Product OptimizationDecember 23, 2024What is Prototype Machining?Prototype machining is a manufacturing process used to create samples or prototypes of a product. It typically uses computer-aided design (CAD) software and computer numeri...view

- Custom Prototype Manufacturing in ConstructionMarch 19, 2024In the construction industry, custom prototype manufacturing is a critical component to ensure a smooth project, and Ripple MFG stands out in the field of custom prototype manufacturing in const...view

- Medical Marvels: Innovations in Prototype Machining for Healthcare DevicesJanuary 5, 2024In today's rapidly advancing world, innovation in the healthcare sector has become essential for better patient outcomes. One area that has seen remarkable progress is prototype machining for heal...view