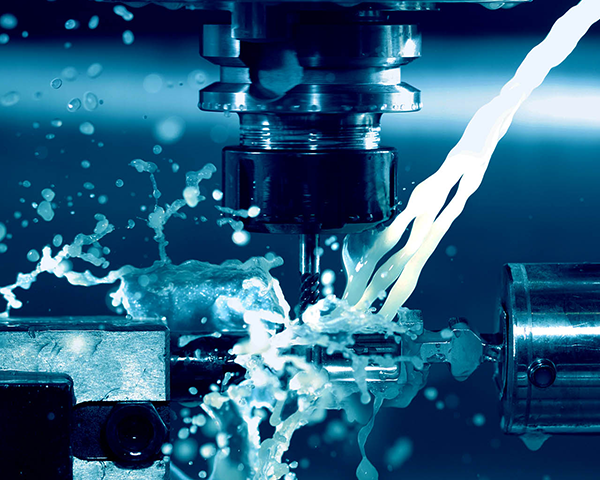

First, precision CNC machining process is concentrated

CNC machine tools generally with automatic tool changer, tool magazine, tool change process automatically controlled by the program, therefore, the process is more concentrated. Process concentration brings great economic benefits, including reducing the machine tool footprint, saving plant and reduce or no intermediate links (such as intermediate testing of semi-finished products, temporary storage and handling, etc.), saving time and manpower.

Second, precision CNC machining automation

Precision CNC machining, no manual control of the tool, a high degree of automation.

1, the requirements of the operator to reduce: an ordinary machine tool senior workers, not a short time can be trained, and a CNC worker without programming training time is extremely short. And, CNC workers on CNC machine tools to process the parts than ordinary workers on traditional machine tools to process the parts of high precision, time to save.

2, reduce the labor intensity of workers: CNC workers in the processing process, most of the time is excluded from the processing process, very labor-saving.

3, product quality and stability: CNC high precision tools processing automation, eliminating the fatigue of workers on ordinary machine tools, carelessness, estimation and other human errors, to improve the consistency of the product.

4, high processing efficiency: CNC machine tools such as automatic tool change makes the processing process compact, improving labor productivity.

Third, precision CNC machining to adapt to market competition

Precision CNC machining services as long as you change the program, you can process new parts on the CNC machine tool, and can automate the operation, good flexibility, high efficiency, so the CNC machine tool can well adapt to market competition.

Fourth, precision CNC machining capability

Machine tools can accurately process a variety of contours, and some contours in ordinary machine tools can not be processed. CNC machine tools are particularly suitable for the following occasions: no scrap parts, new product development and urgent parts of the processing.

Precision CNC machining than traditional machine tool processing has changed a lot, the efficiency is also greatly improved, which is also the benefit of the continuous development of science and technology.

- Urethane Casting for Custom Parts: Your Key to InnovationOctober 27, 2023Innovation is the lifeblood of progress in product development, and for those seeking to create custom parts with precision and flexibility, urethane casting services are emerging as a pivotal solutio...view

- How Much Do You Know About The Process -- Vacuum CastingFebruary 27, 2023Why vacuum castingIn our daily life, we often apply to plastic products, in general products, the use of more thermoplastics, this plastic in industrial production, generally with thermoforming, can b...view

- The Impact of Prototyping Machining Services in ArchitectureMarch 19, 2024With the advancement of science and technology, prototype machining services are increasingly used in the field of architecture, which has a profound impact on architectural design, construction and m...view

- Precise Tool and Manufacturing Technology: The Precise Force Driving Industrial ProgressSeptember 18, 2024The Importance of Precise Tool and Manufacturing TechnologyIn modern industry, the application of precise tool and manufacturing is becoming increasingly widespread. They are not only a symbol of tech...view

- Unlocking the Benefits: Urethane Casting Service ExplainedOctober 27, 2023In the world of rapid prototyping and low-volume production, urethane casting has emerged as a versatile and cost-effective method. Urethane casting services offer a wide array of benefits that can re...view

- Sports Equipment Redefined: Urethane Casting Services in Athletic Gear ManufacturingJanuary 5, 2024In the ever-evolving world of sports gear manufacturing, innovation is key to staying ahead of the game. As athletes continually strive to push their limits, manufacturers must find ways to deliver eq...view