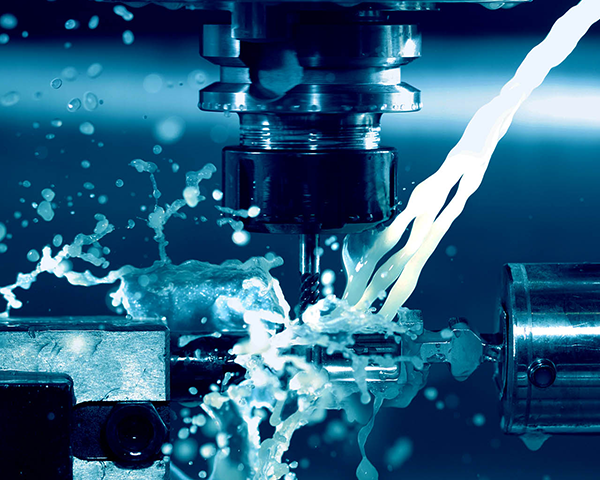

5 axis CNC machining is an advanced manufacturing process that utilizes five axes of motion to cut and shape materials. This technology is an improvement over the traditional 3 axis machining process, as it allows for greater flexibility and precision in machining complex parts. The additional two axes (A and B) provide more freedom of movement to the cutting tool, which can approach the material from various angles, allowing for more intricate and precise cuts.

There are several advantages to using 5 axis CNC machining over traditional 3 axis machining. Here are some of the most significant advantages:

5 axis CNC machining can improve accuracy and accuracy

One of the most significant advantages of 5 axis CNC service is its ability to produce highly precise and accurate parts. The additional two axes allow the cutting tool to approach the material from different angles, resulting in more intricate and precise cuts. This increased precision and accuracy is essential in industries such as aerospace and medical device manufacturing, where even the slightest deviation from specifications can have significant consequences.

5 axis CNC machining can reduce setup time and improve efficiency

5 axis CNC machines are equipped with advanced software that allows for faster set-up times and increased efficiency. The software can automatically adjust the cutting tool's position and orientation, eliminating the need for manual adjustments. This reduces the time required for set-up and increases the overall efficiency of the machining process.

5 axis CNC machining has greater flexibility and versatility

5 axis CNC machines offer greater flexibility and versatility than traditional 3 axis machines. The additional two axes allow for more freedom of movement, enabling the cutting tool to approach the material from different angles. This flexibility and versatility make 5 axis CNC machines ideal for machining complex and irregularly shaped parts.

5 axis CNC machining to reduce material waste

As one of the precision tool making, 5 axis CNC machining allows for more precise cuts, which can significantly reduce material waste. This is particularly important in industries such as aerospace and automotive, where materials such as titanium and carbon fiber can be expensive.

5 axis CNC machining reduces labor costs

5 axis CNC machines require less labor than traditional 3 axis machines. The advanced software allows for faster set-up times and increased efficiency, which can reduce the number of operators required to run the machine. This can result in significant cost savings for manufacturers.

- How Is Prototyping Used in the Automotive Industry?July 22, 2023Automotive rapid prototyping is an essential process used in the automotive industry to develop new vehicles and components. Prototyping allows designers and engineers to test and refine their ideas b...view

- Optimize Product Development Cycle with Custom Prototyping ServicesJune 14, 2024Molds are indispensable basic technological equipment in the manufacturing industry, primarily used for efficient mass production of various industrial product components and parts. They are widely ap...view

- What Is Precision Injection Molding?December 23, 2024Precision injection molding refers to an injection molding method where the dimensional repeatability of the molded products is very high, making it difficult to achieve the required standards using g...view

- A Guide to CNC Prototype ManufacturingSeptember 1, 2023What is CNC Prototype Manufacturing?CNC prototype manufacturing is a type of prototype manufacturing that uses Computer Numerical Control (CNC) machines to create physical prototypes of products. CNC ...view

- Advantages of Urethane Molds Compared to Traditional MoldsJune 14, 2024When using traditional steel molds for processing, due to the extremely thin material of the parts, the clearance between the punch and die must be sufficiently small, even close to zero-clearance pun...view

- Automotive Ingenuity: Revolutionizing Vehicle Design with Prototype MachiningJanuary 5, 2024In the modern automotive industry, innovation and technology play an integral role in shaping the future of vehicles. One process that stands out amidst this evolution is prototype machining. With its...view

_20250123.webp)