In the dynamic realm of product development, where ideas evolve into tangible innovations, the role of prototype machining stands as a cornerstone for success. The journey from concept to market-ready product is a complex one, and prototype machining emerges as a pivotal step that unleashes innovation and refines designs with precision.

Prototyping: A Gateway to Innovation

At the heart of any groundbreaking product is the process of prototyping, and prototype machining is the conduit that transforms abstract ideas into tangible realities. Before a product can go into mass production, it undergoes several iterations to ensure that the design aligns with the envisioned functionality, aesthetics, and manufacturability. This iterative process is fundamental in the innovation cycle, allowing engineers and designers to test, refine, and perfect their concepts.

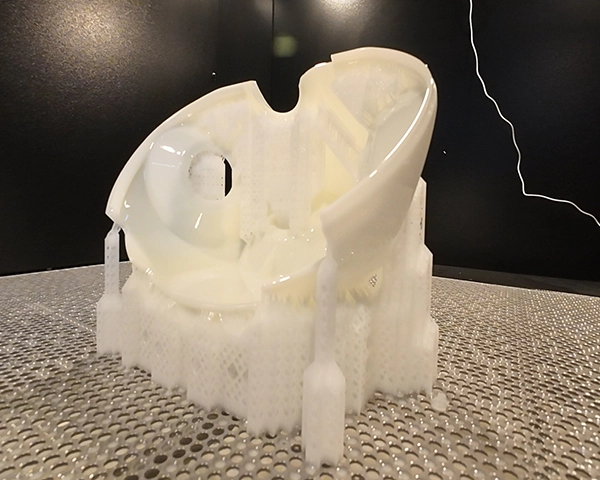

Prototype Machining Defined:Prototype machining involves the creation of physical models or prototypes using subtractive manufacturing processes like milling, turning, and drilling. These processes allow for the precise shaping of materials, enabling engineers to create functional prototypes that closely resemble the final product.

Precision in Design Refinement

The first stage of prototyping involves transforming initial sketches and digital designs into physical prototypes. This is where prototype machining takes center stage. Engineers use Computer Numerical Control (CNC) machines to meticulously carve out components based on the design specifications. This level of precision is crucial in ensuring that every detail of the product is accurately represented in the prototype.

With the first prototype in hand, designers and engineers can assess its performance, functionality, and aesthetics. It serves as a tangible representation that allows for hands-on testing and evaluation. If improvements or modifications are needed, the iterative refinement process begins. Prototype machining facilitates this by providing a quick and accurate means to implement changes and enhancements. Whether it's adjusting dimensions, refining contours, or optimizing material choices, prototype machining allows for swift iterations that significantly accelerate the design refinement process.

Accelerating Time-to-Market with Prototype Machining

In the fast-paced landscape of product development, time is often a critical factor. The efficiency of prototype machining plays a pivotal role in accelerating the time-to-market for innovative products. Unlike traditional manufacturing methods that may require extensive tooling and setup, prototype machining offers a rapid and cost-effective solution. CNC machines can quickly produce precise prototypes, allowing designers to assess multiple design variations in a shorter timeframe.

The advent of rapid prototyping techniques, such as 3D printing, further amplifies the impact of prototype machining. These methods enable the creation of intricate and complex geometries with speed and efficiency. While traditional machining methods remain essential for certain applications, rapid prototyping techniques provide an additional dimension to the prototyping process, allowing for even quicker iterations and design validation.

Ensuring Functional Validations and Quality Assurance

Beyond the visual and aesthetic aspects, prototype machining is instrumental in conducting functional validations and ensuring the quality of the final product. As prototypes are machined to mirror the intended materials and manufacturing processes of the final product, engineers can assess factors such as structural integrity, durability, and overall performance.

By subjecting prototypes to real-world conditions, engineers can simulate the stresses and strains the product will encounter during its lifecycle. This real-world testing is invaluable for uncovering potential weaknesses, refining material choices, and enhancing the overall robustness of the design. Prototype machining allows for the creation of prototypes that closely mimic the intended production materials, providing a realistic testing ground for product performance.

In conclusion, the role of prototype machining in product development is transformative. It serves as the bridge between imagination and reality, allowing innovators to refine their concepts with precision and efficiency. From the initial stages of design refinement to the crucial steps of functional validation, prototype machining is an indispensable tool that accelerates innovation and ensures the delivery of high-quality, market-ready products.

- Advantages of Urethane Molds Compared to Traditional MoldsJune 14, 2024When using traditional steel molds for processing, due to the extremely thin material of the parts, the clearance between the punch and die must be sufficiently small, even close to zero-clearance pun...view

- Navigating the Nanoworld: High Precision Tools in Nanotechnology ApplicationsJanuary 5, 2024Welcome to the fascinating world of nanotechnology, where scientists and engineers manipulate matter at the tiniest scale. Unlocking the potential of this field requires the use of high precision tool...view

- A Guide to CNC Prototype ManufacturingSeptember 1, 2023What is CNC Prototype Manufacturing?CNC prototype manufacturing is a type of prototype manufacturing that uses Computer Numerical Control (CNC) machines to create physical prototypes of products. CNC ...view

- What Is Precision Injection Molding?December 23, 2024Precision injection molding refers to an injection molding method where the dimensional repeatability of the molded products is very high, making it difficult to achieve the required standards using g...view

- Sculpting the Future: 4 Axis CNC Machining Suppliers for Artistic CreationsNovember 23, 2023Art and technology converge in a symphony of precision, giving rise to a new era in creative expression. As artists push the boundaries of their craft, the collaboration with cutting-edge technology b...view

- Development History Of Injection MoldingFebruary 27, 2023Introduction to Injection Molding Injection molding is also known as injection molding, which is a kind of injection and molding method. The advantages of injection molding method are fast production ...view